Automated machine & process systems for manufacturing

Modern manufacturing facilities requires highly effective automated control over production processes and equipment.

At AutomateIT, we are specialists in plantwide floor system control and automation integration, developing reliable and cohesive solutions that integrate the equipment on your plant floor for faster more-efficient production.

email us at sales@automateit.net

or call 417.429.4320 | Toll Free 866.576.7584

Industry-specific expertise

Decades of experience across all manufacturing sectors, including automotive, electronics, food, industrial and pharmaceuticals.

Tailored solutions for every business

We design systems aligned with your unique goals and deliver according to plan and budget.

Comprehensive support

End-to-end service, from initial consultation to ongoing support.

Scalable, future-proof systems

Flexible designs that grow and adapt with your business needs.

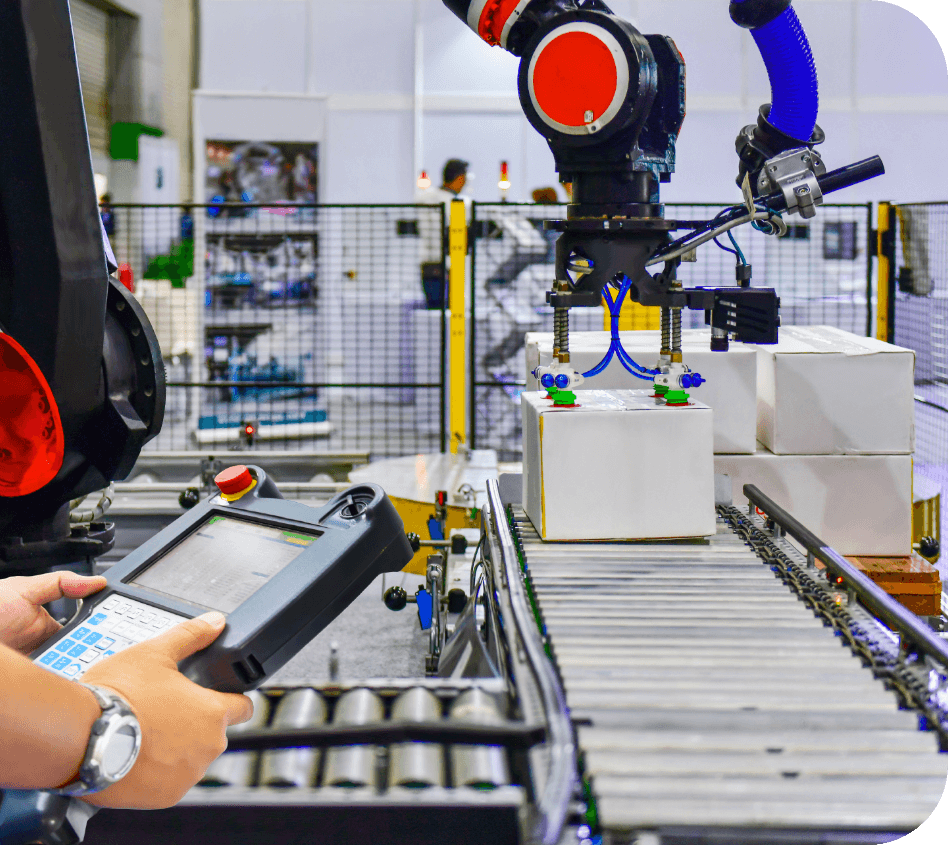

Industrial control architecture and automation experts

Our technicians and engineers are experts in all key industrial control architectures, including PLC/HMI, PLC-based SCADA, DCS and S88 batch control systems.

That gives us the capacity to develop and design integrated platforms to control a vast array of componentry and equipment, from motor control centers and power services, to proximity switches and transmitters and make them operate in unison plantwide for higher efficiency, output, and quality.

Upgrades, migrations and multi-site capabilities

We design for operational co-integration, serviceability and long-term scalability, and bring the ability to deliver:

- Intuitive and reliable plant floor automation

- New systems and legacy upgrades and migrations

- Multi-site system capabilities for system-wide visibility and control

- Transparent data sharing using standardized underlying software and hardware

Our automation system capabilities

Electrical design

Electrical system schematic development, power and environmental design, power distribution and monitoring.

Control panel systems

Customized UL 508A-compliant industrial control panel solutions for packaging, process, facilities, utilities, and other industrial applications. Factory tested and certified for ready for production.

Packaging controls

Turnkey production controls and monitoring systems to oversee material handling, labelling, printing, inspection, safety controls and secondary packaging requirements.

Process controls

Full-scale industrial batch processing solutions including instrument specification, control design and PLC, DLC or HMI programming.

Information solutions

Operational data acquisition and analytics that use SCADA, middleware applications, and ERP integration to provide enterprise manufacturing intelligence, KPI reporting and performance monitoring.

System support

Remote system monitoring available for technical support and troubleshooting.

Our services

Automated material handling

Reliable, efficient systems for storage and movement.

Precision assembly solutions

Maintain quality across complex processes.

Integrated quality inspection and testing

Detect and resolve issues in real-time.

Process optimization and consulting

Maximize ROI by eliminating production bottlenecks.

Benefits of choosing AutomateIt

Cost savings

We can help you to reduce labor costs, minimize unplanned downtime, and lower waste.

Enhanced productivity

We can deliver automation and AI-driven solutions for round-the-clock operations for maximized output.

Consistent quality

We are experts in system automation and monitoring solutions to maintain high standards for every product.

Improved safety

Proven system control and safety solutions to increase workplace safety.

We have the people and the engineering solutions to guide you through your Industry 4.0 & AI journey

Contact us for a free consultation to see how our tailored automation solutions can boost your efficiency, quality, and growth.